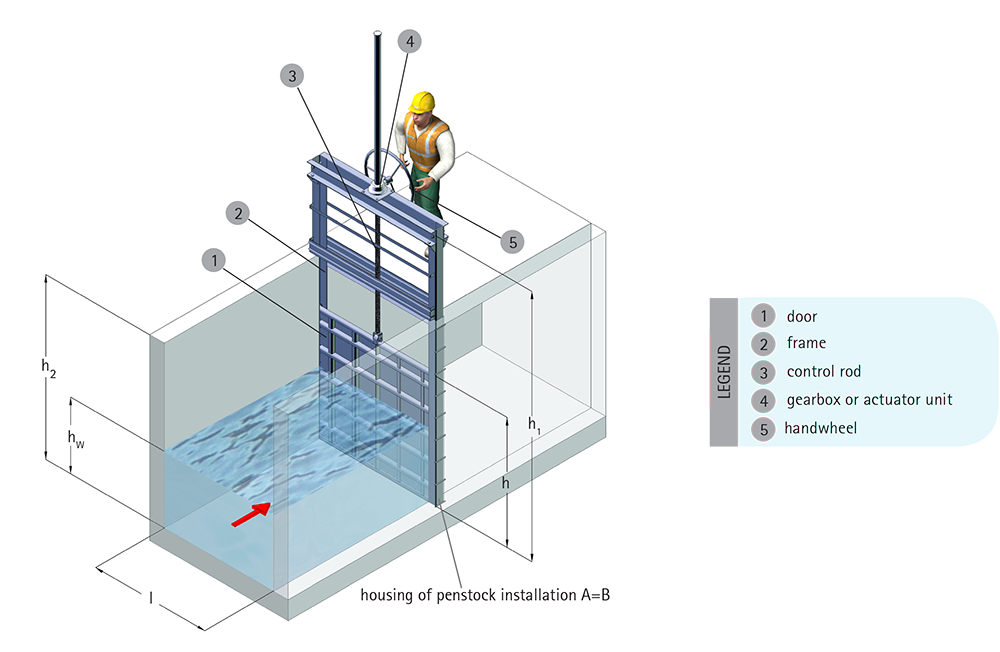

PV3 model is a penstock with seal on three sides, i.e. on the low horizontal side and on the two vertical sides. It is generally used for installation in channels where it is necessary to intercept and control the flow of fluid or, in some cases, also for wall installation, for example on the outlet or the inlet of a channel.

When operating, the penstock slides perpendicularly to the direction of the flow and it is moved by the screw by means of selected control units. The seal is given by the rubber gaskets, in both directions, together with the wedges that exerting an horizontal thrust on the sealing surfaces only when the penstock is closed, facilitate the opening and closing of it.

The tables give an indication of the manoeuvring force, the hydraulic thrust and the weights of PV3 model. TABLE A refers to penstocks with “unseating” head and TABLE B refers to penstocks with “seating” head.

| l mm |

h mm |

hw mm |

h2 mm |

Weight kg |

Force Nm |

A’ mm |

A=B mm |

|---|---|---|---|---|---|---|---|

| 300 | 300 | 200 | 1000 | 69 | 1,8 | 8 | 100 |

| 400 | 400 | 300 | 1000 | 82 | 3,3 | 8 | 100 |

| 500 | 500 | 400 | 1000 | 107 | 5,6 | 8 | 100 |

| 600 | 600 | 500 | 1000 | 120 | 7,6 | 8 | 100 |

| 700 | 700 | 600 | 1000 | 135 | 16,4 | 8 | 100 |

| 800 | 800 | 700 | 1000 | 155 | 19,5 | 8 | 100 |

| 900 | 900 | 800 | 1500 | 183 | 26,9 | 8 | 100 |

| 1000 | 1000 | 900 | 1500 | 205 | 36,2 | 8 | 100 |

| 1100 | 1100 | 1000 | 1500 | 226 | 47,2 | 8 | 100 |

| 1200 | 1200 | 1100 | 1500 | 249 | 60,5 | 8 | 100 |

| 1300 | 1300 | 1200 | 2000 | 303 | 76,3 | 8 | 100 |

| 1400 | 1400 | 1300 | 2000 | 336 | 94,9 | 8 | 100 |

| 1500 | 1500 | 1400 | 2000 | 387 | 109,3 | 8 | 100 |

| 1600 | 1600 | 1500 | 2000 | 517 | 146,9 | 55 | 150 |

| 1700 | 1700 | 1600 | 2500 | 577 | 175,6 | 55 | 150 |

| 1800 | 1800 | 1700 | 2500 | 665 | 253 | 55 | 150 |

| 1900 | 1900 | 1800 | 2500 | 822 | 297,5 | 55 | 150 |

| 2000 | 2000 | 1900 | 3000 | 900 | 184,8 | 105 | 200 |

| 2100 | 2100 | 2000 | 3000 | 982 | 211 | 105 | 200 |

| 2200 | 2200 | 2100 | 3000 | 1111 | 239,5 | 105 | 200 |

| 2300 | 2300 | 2.200 | 3000 | 1189 | 271,7 | 105 | 200 |

| 2400 | 2400 | 2.300 | 3.000 | 1332 | 310,8 | 105 | 200 |

| 2500 | 2500 | 2.400 | 4000 | 1405 | 348,7 | 105 | 200 |

| 2600 | 2600 | 2.500 | 4000 | 1591 | 465,9 | 105 | 200 |

| 2700 | 2700 | 2.600 | 4000 | 1614 | 512,3 | 105 | 200 |

| 2800 | 2800 | 2.700 | 4000 | 1715 | 568,4 | 105 | 200 |

| 2900 | 2900 | 2.800 | 4.000 | 1886 | 634 | 105 | 200 |

| 3000 | 3000 | 2.900 | 4.000 | 2085 | 811 | 105 | 200 |

| 3200 | 3200 | 3.000 | 4.000 | 2403 | 982 | 105 | 200 |

| 3400 | 3400 | 3200 | 5.000 | 3258 | 1318 | 155 | 250 |

| 3600 | 3600 | 3400 | 5.000 | 3487 | 1539 | 155 | 250 |

| 3600 | 3600 | 3400 | 5.000 | 3487 | 1539 | 155 | 250 |

| l mm |

h mm |

hw mm |

h2 mm |

Weight kg |

Force Nm |

A’ mm |

A=B mm |

|---|---|---|---|---|---|---|---|

| 300 | 300 | 200 | 1000 | 69 | 1,8 | 8 | 100 |

| 400 | 400 | 300 | 1000 | 82 | 3,3 | 8 | 100 |

| 500 | 500 | 400 | 1000 | 107 | 5,6 | 8 | 100 |

| 600 | 600 | 500 | 1000 | 120 | 7,6 | 8 | 100 |

| 700 | 700 | 600 | 1000 | 135 | 16,4 | 8 | 100 |

| 800 | 800 | 700 | 1000 | 150 | 19,2 | 8 | 100 |

| 900 | 900 | 800 | 1500 | 173 | 24,1 | 8 | 100 |

| 1000 | 1000 | 900 | 1500 | 195 | 36,2 | 8 | 100 |

| 1100 | 1100 | 1000 | 1500 | 223 | 47,2 | 8 | 100 |

| 1200 | 1200 | 1100 | 1500 | 246 | 60,3 | 8 | 100 |

| 1300 | 1300 | 1200 | 2000 | 299 | 76,1 | 8 | 100 |

| 1400 | 1400 | 1300 | 2000 | 319 | 93,9 | 8 | 100 |

| 1500 | 1500 | 1400 | 2000 | 387 | 109,3 | 8 | 100 |

| 1600 | 1600 | 1500 | 2000 | 442 | 140,4 | 8 | 100 |

| 1700 | 1700 | 1600 | 2500 | 480 | 166,7 | 8 | 100 |

| 1800 | 1800 | 1700 | 2500 | 521 | 196,6 | 8 | 100 |

| 1900 | 1900 | 1800 | 2500 | 750 | 292,6 | 55 | 150 |

| 2000 | 2000 | 1900 | 3000 | 827 | 340,8 | 55 | 150 |

| 2100 | 2100 | 2000 | 3000 | 902 | 392,3 | 55 | 150 |

| 2200 | 2200 | 2100 | 3000 | 953 | 447 | 55 | 150 |

| 2300 | 2300 | 2200 | 3000 | 1122 | 607 | 55 | 150 |

| 2400 | 2400 | 2300 | 3000 | 1184 | 684,7 | 55 | 150 |

| 2500 | 2500 | 2400 | 4000 | 1337 | 405,5 | 105 | 200 |

| 2600 | 2600 | 2500 | 4000 | 1453 | 454,9 | 105 | 200 |

| 2700 | 2700 | 2600 | 4000 | 1522 | 505,1 | 105 | 200 |

| 2800 | 2800 | 2700 | 4000 | 1693 | 566,7 | 105 | 200 |

| 2900 | 2900 | 2800 | 4000 | 1768 | 625 | 105 | 200 |

| 3000 | 3000 | 2900 | 4000 | 1867 | 688 | 105 | 200 |

| 3200 | 3200 | 3000 | 4000 | 2283 | 971,3 | 105 | 200 |

| 3400 | 3400 | 3200 | 5000 | 2435 | 1145,9 | 105 | 200 |

| 3600 | 3600 | 3400 | 5000 | 2690 | 1492,7 | 105 | 200 |

| 3800 | 3800 | 3600 | 5000 | 3183 | 1767 | 105 | 200 |

NOTES:

The tables show some ”examples” of penstocks. All other dimensions, even the rectangular ones, can be manufactured.

SERECO reserves to recalculate all the penstocks subject of the request for quotation according to the actual dimensions and operating conditions that will be communicated each time through the form “PSF”.

In the tables it has been considered the level h1= h x 2 +1000mm.

LEGEND:

Kg: the weights refer to standard channel mounted penstock with handwheel only or, when necessary, with handwheel and gearbox; the weights do not include the weight of the possible electric actuator.

Nm: necessary torque to operate the driving screw.

A’: door thickness.

A=B: housing for penstock installation.

SERIE: